HIGH VOLTAGE HIGH ENERGY CERAMIC DISC RESISTORS----SILICON CARBIDE BASE

FEATURES

1) 100% ceramic solid die casting structure, mainly composed of zinc oxide, alumina, magnesium oxide and artificial clay

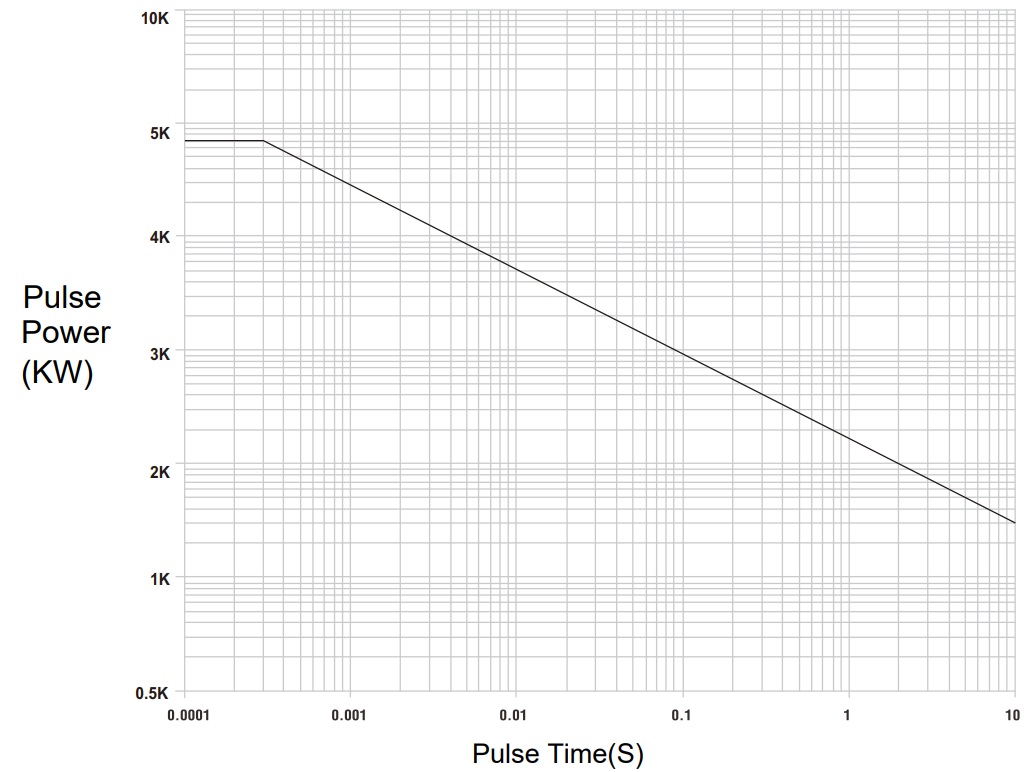

2) Withstand high pulse energy, suitable for ultra-high voltage environment, can be used for circuits above 1000kV, instantaneous power up to 3kkw

3) Non-inductive design,non traditional wire wound and non film structure resistors. Can be used in air, insulation oil, SF6 gas.

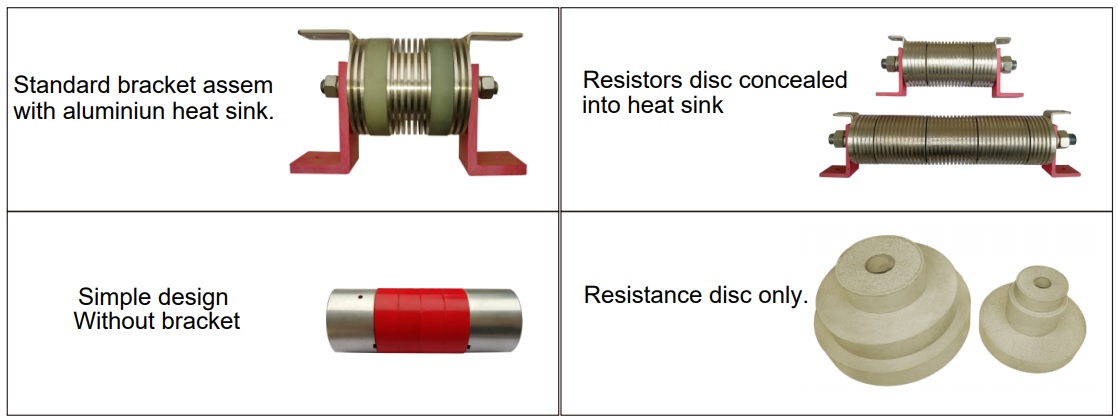

4) Flexible assembly mode , custom requirement acceptable.Series connectioin by resistor disc.

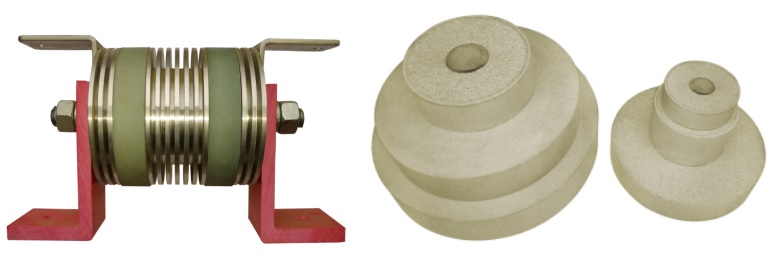

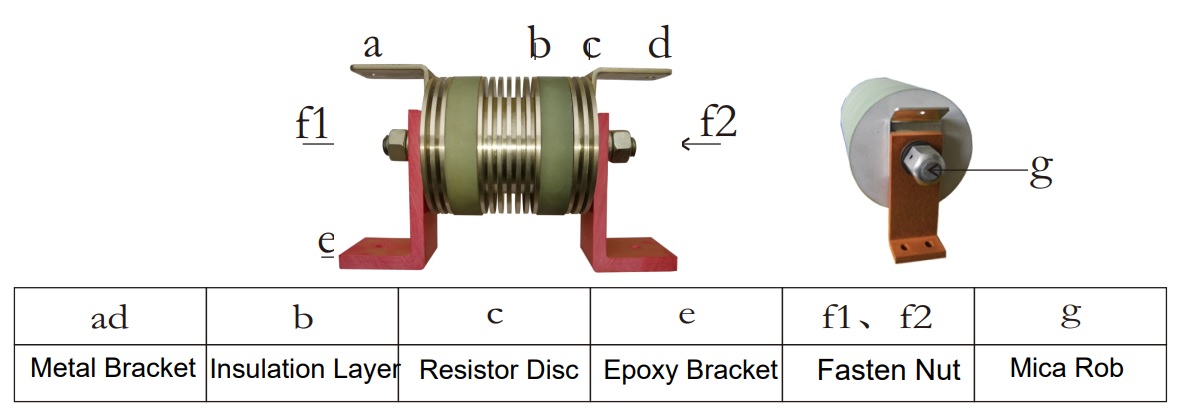

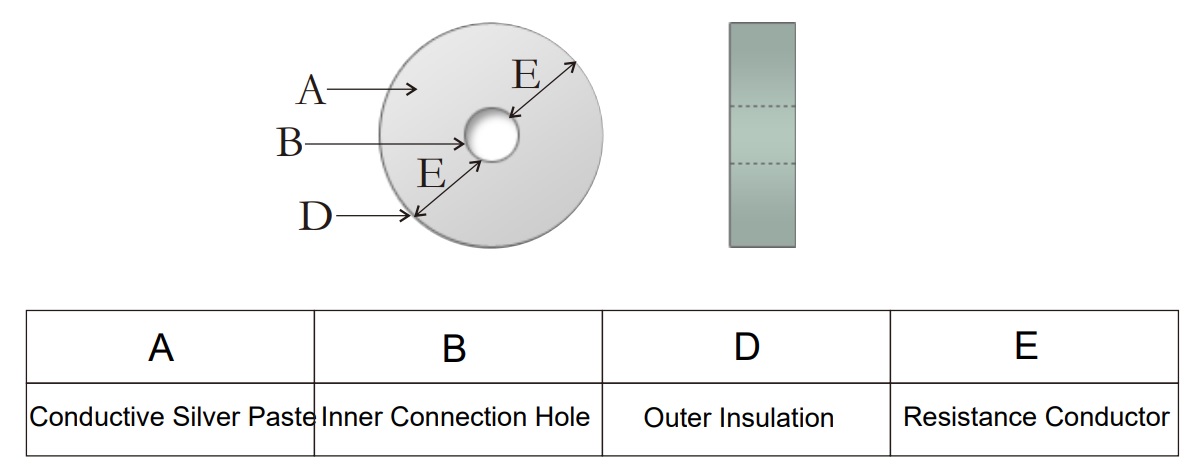

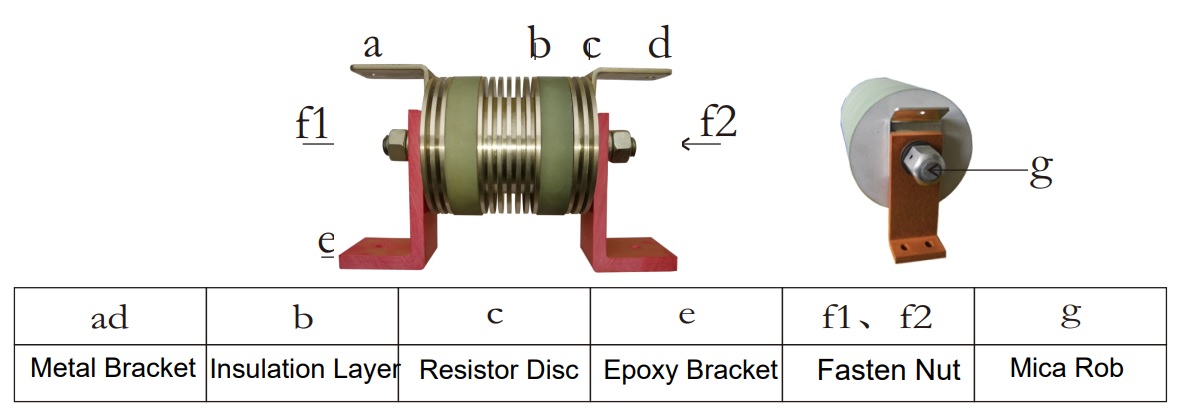

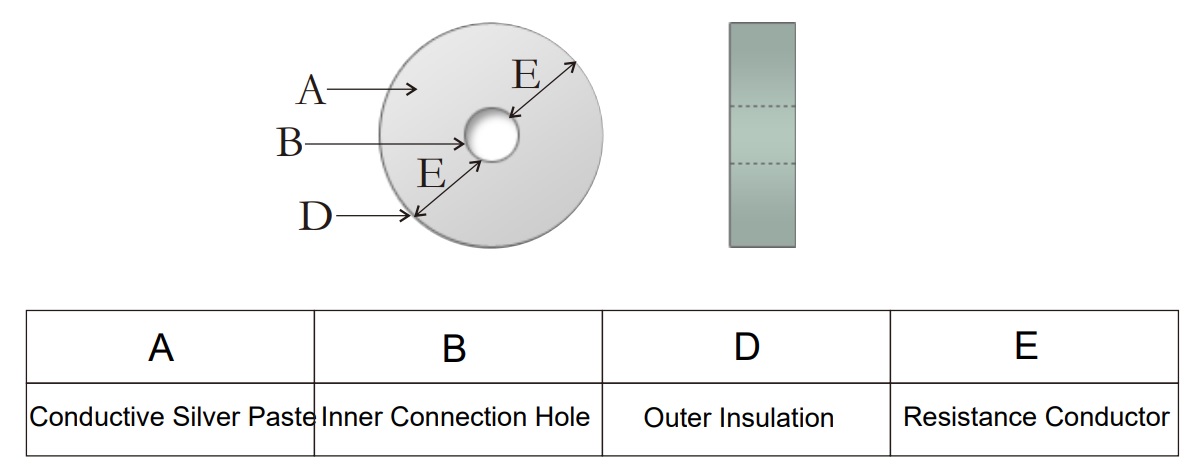

STRUCTURE

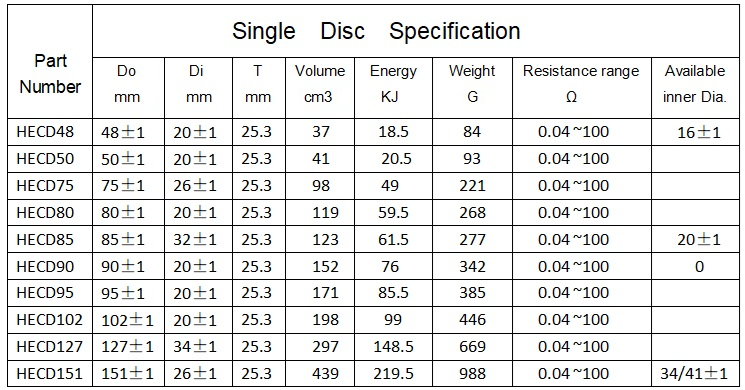

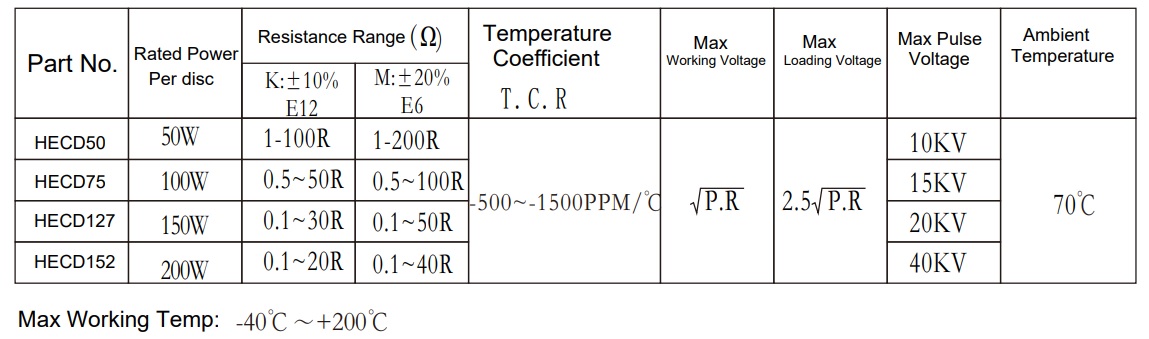

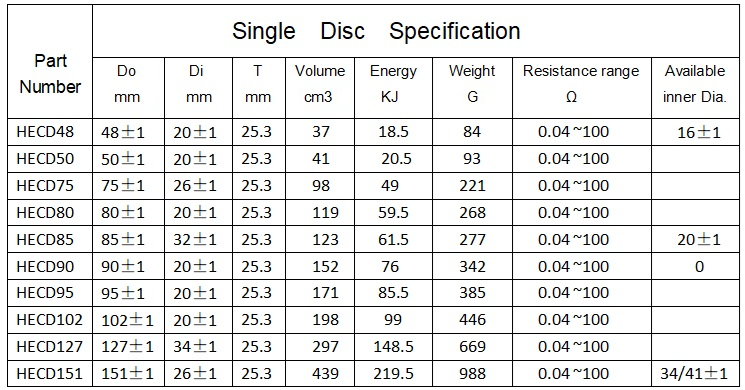

SPECIFICATION

Do:Outer diameter, Di:Inner diameter, T: Thickness

SPECIFICATION

Do:Outer diameter, Di:Inner diameter, T: Thickness

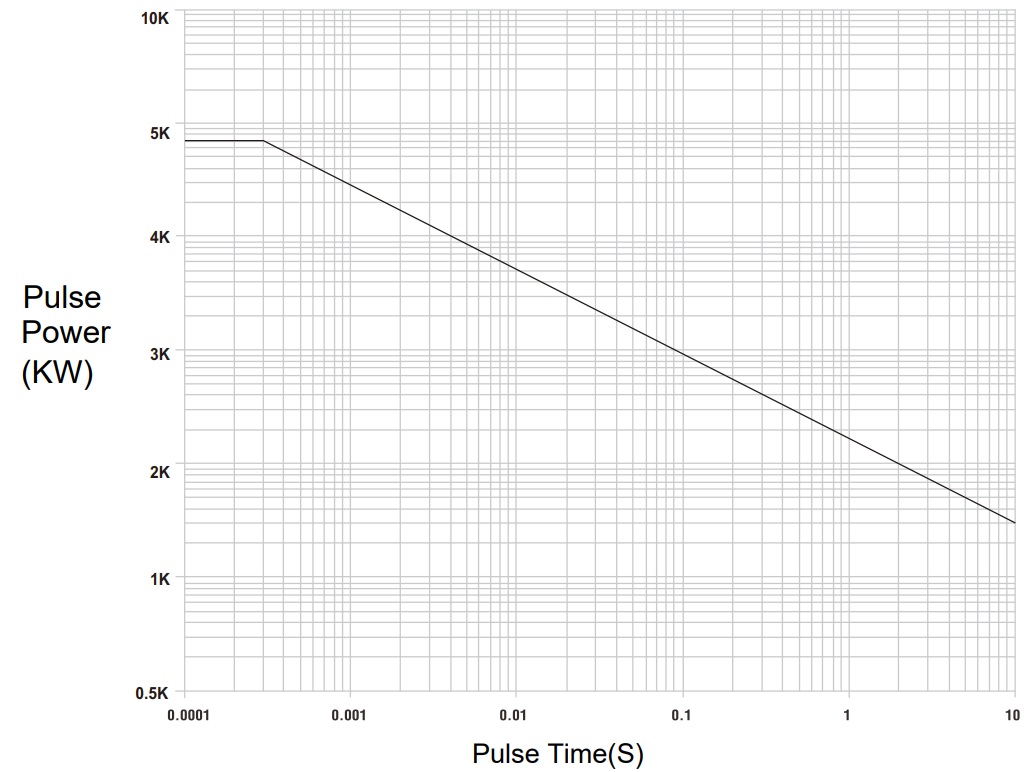

PULSE POWER CURVE(SINGLE PULSE)

PULSE POWER CURVE(SINGLE PULSE)

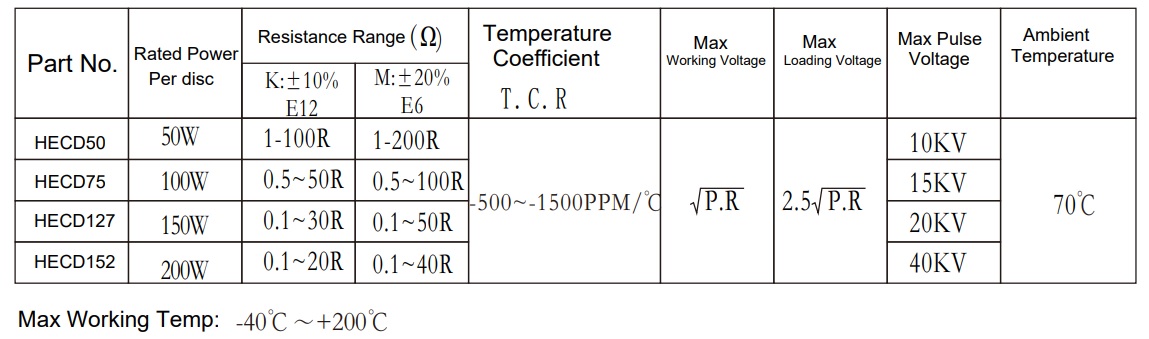

POWER , RESISTANCE RANGE & WITHSTAND VOLTAGE

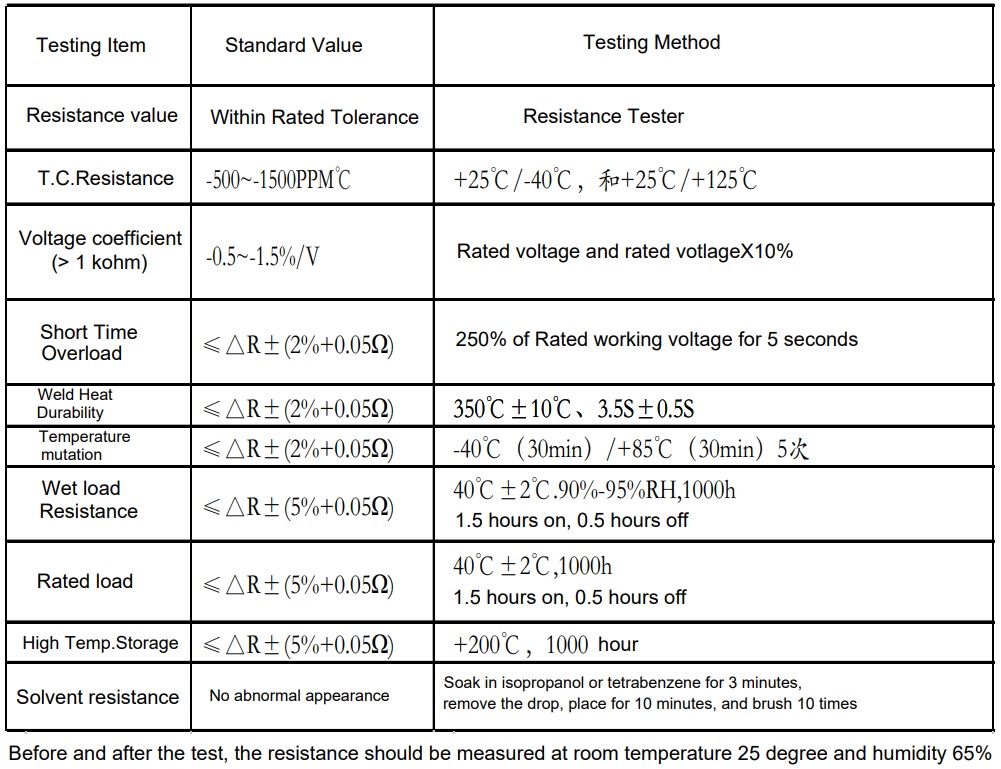

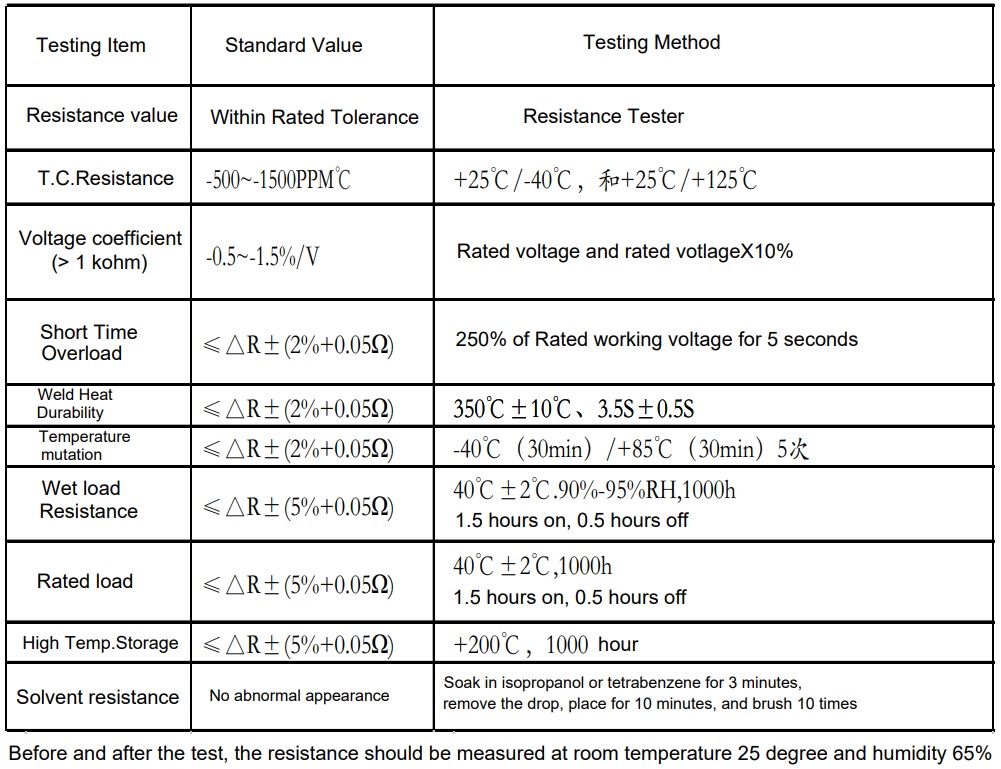

PERFORMANCE

PERFORMANCE

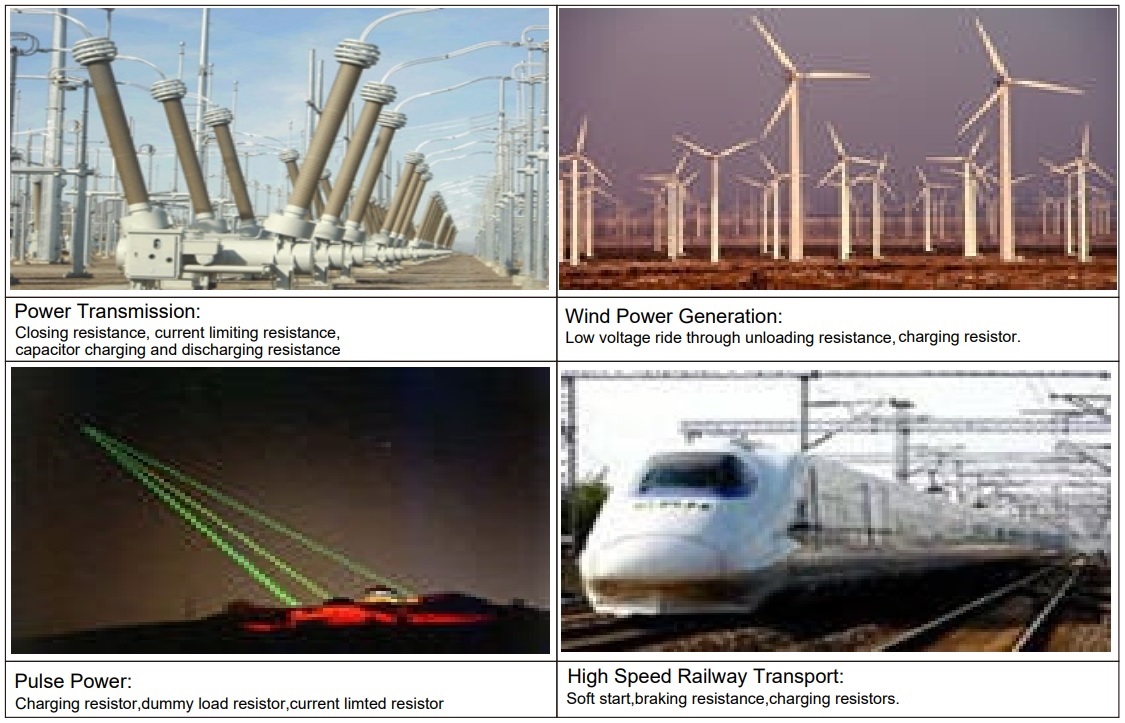

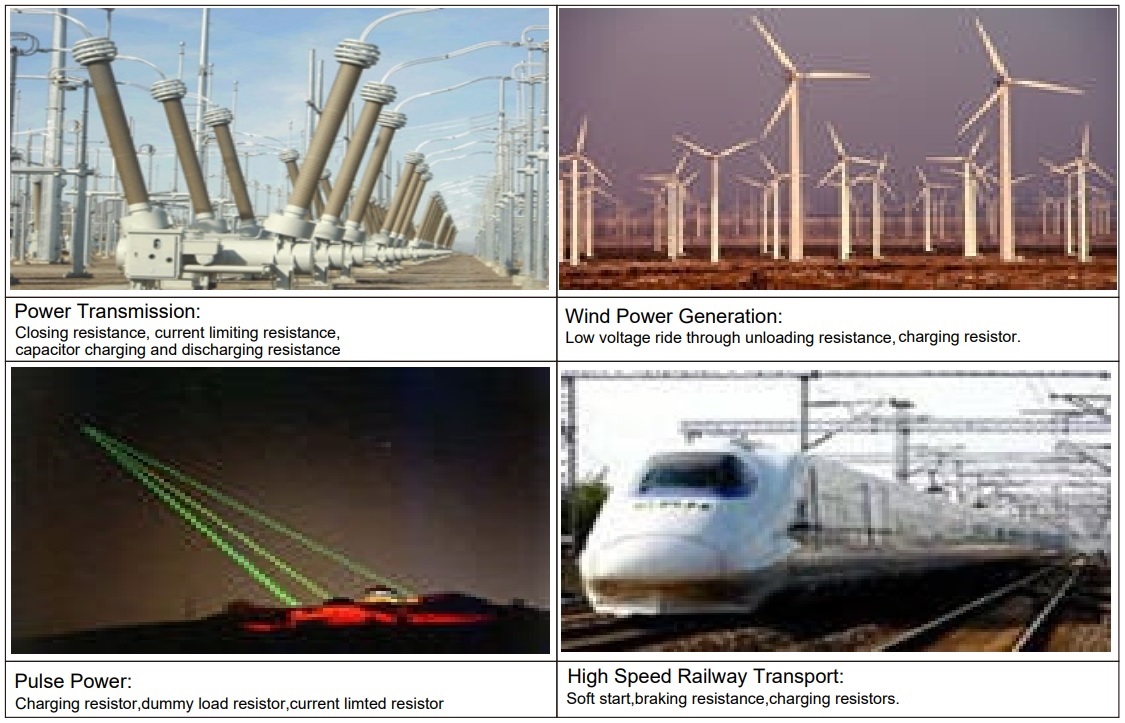

TYPICAL APPLICATION

TYPICAL APPLICATION

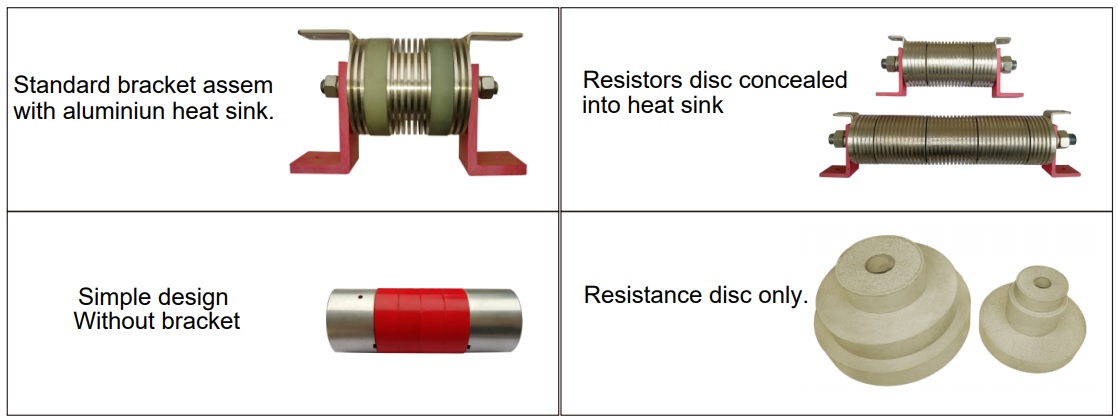

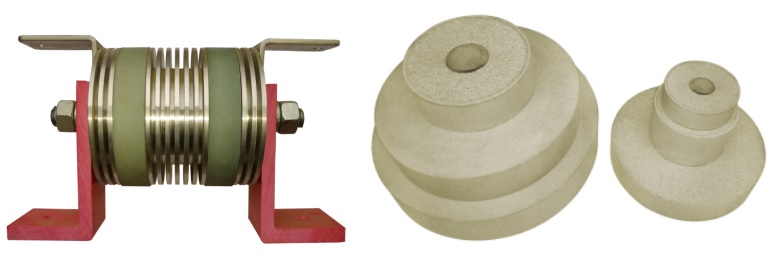

OPTIONAL PRODUCT ASSEMBLY

OPTIONAL PRODUCT ASSEMBLY

Alternative Replacement for HVR Resistors High Voltage High Power High Energy Ceramic Resistors

In 2020, HVC develop new type ceramic disc type high voltage resistor, which using Zinc oxide base material.

Alternative Replacement for HVR Resistors High Voltage High Power High Energy Ceramic Resistors

In 2020, HVC develop new type ceramic disc type high voltage resistor, which using Zinc oxide base material.

This new type of ceramic resistorwith many advance performance compare to traditional metal shell type high

power resistor,also with much higher surge absored ability.

Compare to HVR's original high power resitor, HVC item also get approval by some fast train and smart grid

market customer. They required the high power resistor manufacturer to offer them disc only(mostly for power

electricity machine client) and also assembly type,(majorly for transportantionequipment manufacturer),

welcome to give your design idea and your exisiting HVR drawing, our engineer may offer professional solution.

The performance of zinc oxide based high energy resistance of our company

Zinc oxide ceramic linear resistance is made of composite ceramic resistance inorganic materials, using advanced new ceramic technology, which has incomparable characteristics of traditional resistance. It has unique advantages in high frequency, high current pulse circuit, high energy absorption circuit, non intermittent power supply circuit, especially in the presence of impact energy, peak power, high voltage or low inductance and other conditions The composite ceramic resistor can provide you with a simple and economical solution to solve the industry pain point problem. The product has the advantages of instant absorption of great power, moisture-proof, dust-proof, small size, safety, long life and so on. In terms of performance, it is far more than the carbon black composite resistance at home and abroad. It is a new generation product, which is beneficial for customers to develop new products and create higher value for users

Product advantages

1. High power: the resistance value of the product can be adjusted, and it can withstand high current, and it can be used as high power resistance.

2. Large energy tolerance: the instantaneous energy absorption per cubic centimeter is more than twice that of the clay carbon black ceramic resistance produced in Europe; there is no failure phenomenon of film type and wire wound type resistance, and the reasonable structure makes the energy absorption distribution more uniform.

3. No inductance: about 0.4 uh, equivalent to the inductance of the same length of wire, suitable for high frequency and ultra high frequency environment.

4. High voltage resistance: it can be used in EHV and UHV power transmission system with high power and large heat capacity, and can withstand short-term overload and peak current.

5. Small volume: 1 / 10 - 1 / 2 of the volume of metal resistance and clay carbon black ceramic resistance, suitable for various instruments and equipment.

6. Stable performance: in the long-term use, the change rate of resistance of European clay carbon black ceramics is more than 1000 times, while the change rate of this product is within the design range, with little change.

7. Resistance to humidity, corrosion and oxidation: it can work in extreme environment such as dust, water, oil, high cold, ocean and space.

8. Anti vibration: reasonable structure makes the product have anti vibration function.

9. Safety: evenly absorb the energy in the resistance body to prevent explosion.

10. Long service life: it is a vicious circle phenomenon in the use of carbon black resistor, which is more than 10 times of the service life of carbon black resistor produced in Europe (30 years service life).

Main application industries

1. High voltage resistance of high voltage and ultra-high voltage disconnector.

2. Charge and discharge, large high voltage power equipment grounding protection resistance.

3. Neutral grounding protection resistance of transformer and substation.

4. Discharge protection resistor for wind power generation, nuclear power plant and photovoltaic generator set.

5. Large current and high power resistance required by electrical and power equipment in an instant.

6. High speed locomotives, cranes, elevators and other braking frequency conversion resistance harmonic elimination resistance.

7. Heating and non inductive resistance in aviation and aerospace field.

8. Corrosion resistance for offshore oil platforms, ships and warships.

9. Resistance capacitance absorption resistance of thyristor protection circuit.

10. Equipment soft start, current limiting, converter, capacitor discharge, false load and other fields.